Oftentimes, Australian 4WDers are way too quick to take a proverbial deuce over anything that challenges the macho mentality dominating the industry. If a vehicle doesn’t have a certain badge, or is lacking a monster motor with a thong-slapping three-inch straight-through exhaust for ‘bulk soot’, you can forget about ever turning heads as you drive down the street. So what drives someone to replace proven internal combustion engine (ICE) technology with an electric donk, generally reserved for 2WD city cars that can never venture far from a charge point?

If you ask the diesel diehards, they’ll tell you that it’s a waste of time, an exercise in futility. But when everyone seems content to simply bolt on accessories to mainstream makes and models, is this the breath of fresh air we need? The thought process and knowledge behind undertaking an electric vehicle (EV) conversion, let alone on a 4WD, is something that deserves attention and appreciation. I needed to find out what spurred Don to undertake the swap on his 1973 Land Rover Series III Lightweight.

The owner

Don has always gravitated towards electronics. As a young boy, he grew from disassembling radios to find out how they worked, into taking on extra electric projects after school and eventually landing a job in Telstra handling telecommunications. That affinity continued into his adult life, with a brand-new computer stripped down to countless pieces mere hours after arriving in the attic, just to find out “what makes it work”.

Having a father who worked in forestry, he was knee high to a grasshopper when he picked up his love for Land Rovers. Over the years, he estimates about 20 Rovers have been in his shed, so it seems fitting that eventually his two passions should unite and create something truly memorable.

Initially, he planned to EV (electric vehicle) convert a Chrysler PT Cruiser of all things, even going as far as purchasing a shell, but found out that due to airbag compliance he would need to build two and have one crash tested to meet ADRs. In a stroke of sheer coincidence, while Don and his wife were touring in their Iveco Daily towing a caravan around Australia, he happened across the Lightweight sitting in his own driveway, up for grabs from the tenants renting his house. A few quick phone calls and he was the proud owner of yet another Landy, although this time it would be receiving a shiny new electric pacemaker.

The conversion

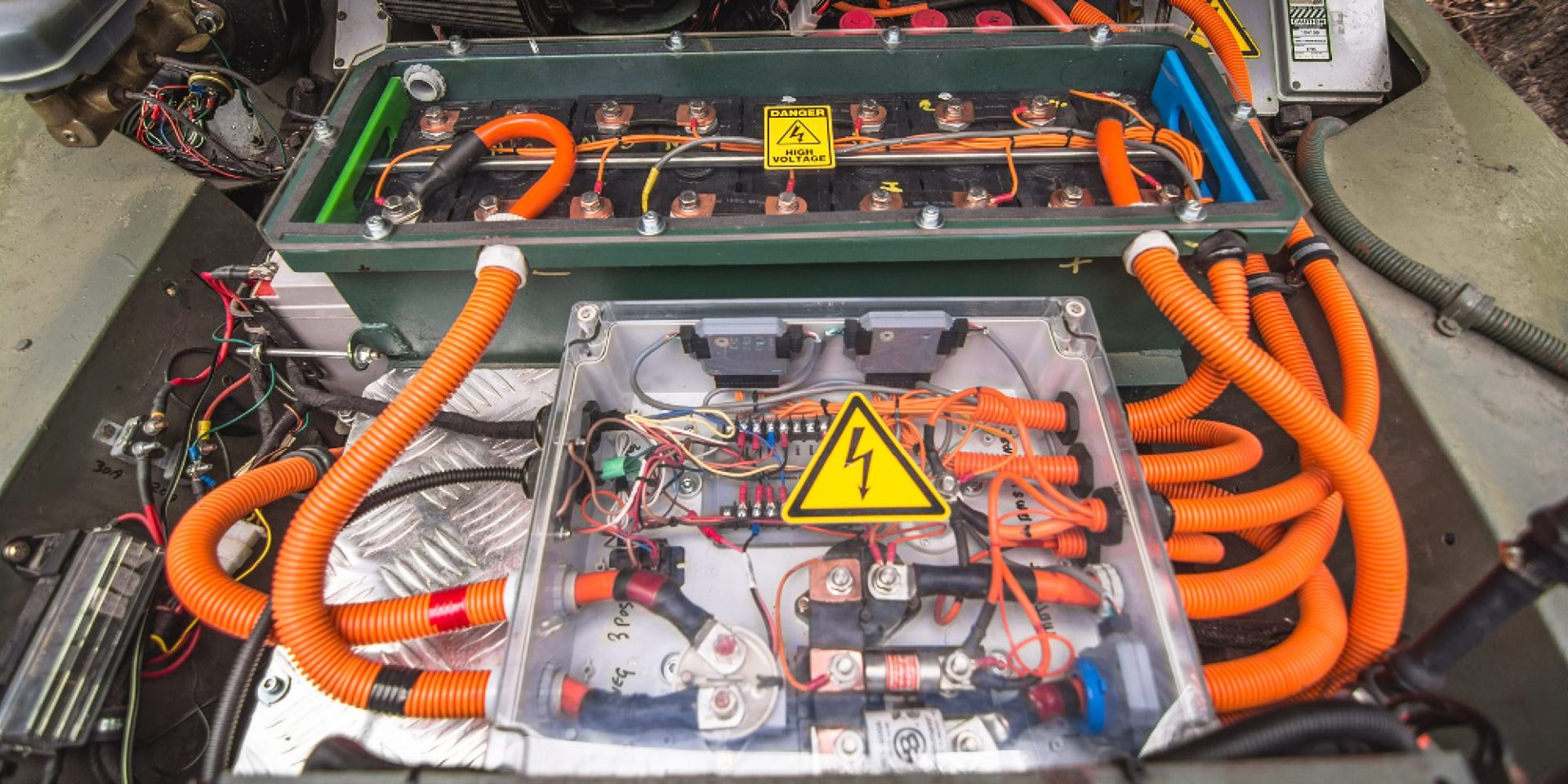

Don began the conversion in late 2017 and a mere three months later in the early new year, the Landy was powering down the street on its maiden voyage. Don opted for an AC motor as he wanted regenerative braking, a feature that the cheaper DC offerings often skimp on. When it arrived from WA, he was quick to make sure that the Canadian EV adaptor plate would bolt up, and as it turns out, it required some ‘faffing about’.

A fair bit of material was removed from the crank flange and motor shaft to get the adaptor plate to sit where he needed it, but the end result meant he could maintain his factory manual transmission and transfer case. Even though the motor can handle more than 10,000rpm, the dated tranny would be flat out at 5000rpm, so the conservative tune, which is loaded via the inbuilt tuner (a stand-alone plug-in programmer is on the cards), limits the revs to 4500 at 110km/h. The optimum speed is around 80km/h, as wind resistance still proves a hindrance to economy (or in this case, range).

How is it in low-range?

The tuner can program the throttle map, remove lag, improve regenerative braking and most importantly, activate eco-mode. Eco-mode limits power output and extends the range to total more than 160km, although you could crawl around in low-range all day worry-free thanks to the charge recovered from braking. Low-range is also a delight, with 100% torque delivery from the moment you begin to move. Don told me he had to control power delivery to avoid breakages at take-off. Now power has been programmed to deliver once the wheels begin to turn, so it won’t sit on the spot and dig holes or shear an axle from the massive load at takeoff. He wasn’t taking chances though, upgrading the axles to a heavy-duty variety and building both front and rear diff locks to plant the power firmly into the earth.

The system runs off a 28.8kWh bank of lithium LiFePo4 batteries that contain no corrosive acid or explosive gasses. Don remarks that the choice was easy, as they offer an 80% depth of discharge and a much greater lifespan for a third of the weight of traditional lead-acid batteries. Plus, the entire system is safer than having the volatile fuel stored in the factory under-seat tanks!

There is only around 60m of cabling in the vehicle, even less than modern 4WDs have in their spaghetti-like wiring harnesses. A necessary expense was the high-voltage cable, orange to alert first responders in the event of an accident. Even though a slightly better, completely sealed motor came out two weeks after Don purchased his, I had also thought that dust ingress would pose an issue but no issues have presented with the current motor.

Watch an update video here

Due to VSB/ NCOP14 (the stringent requirements for engineering) a sturdy battery box was folded up at the local engineers to meet crash specifications and prevent batteries from hurling out. An inertia switch was also installed to cut power if things go pear shaped. VicRoads passed the Landy without issue, as the entire vehicle is compliant and insured.

How much did this EV conversion cost?

The conversion ran Don about $20k, but a substantial portion of that is tied up in batteries and the motor, both of which have cheaper options available for someone looking to complete a similar conversion on a much tighter budget. Realistically, with the price of fuel, naysayers could not disagree that the same amount would disappear into their fuel tank over a couple of years. I would love to keep talking tech specs, but I’m limited in what I can squeeze onto this page.

What has broken?

Two-fifths of bugger-all. This is usually the part in which I would rattle off the list of broken parts and why the owner had to upgrade them to handle the abuse, but meticulous planning and some help from good old Google, allowed the build to progress without major incident. The only issue with the electrical system came from receiving one faulty battery, which was quickly swapped out. The only other thing worth a mention is the original golf buggy throttle had to be replaced with one from a Honda CR-V, but yet again, no issues have presented since.

Final thoughts

A big question I had was how it would drive compared to traditional ICE 4WDs. But after spending a day with the vehicle, I agree with Don that you cannot compare them fairly; they differ far too much in their performance both on and off-road. The complete absence of engine noise, the ability to take off in any gear with no need to slip the clutch, the ease with which it climbed up slippery sections of track that my ever-faithful camera car needed two or three attempts at, was mind-boggling. It has left no doubt in my mind that EV will play an ever-increasing role in the Australian 4WD scene as technology infiltrates the market.

Something Don said to me about five minutes after I met him will stick with me: “People have one view and they don’t see it the other way. But once you drive an EV or once you’ve been in one, that changes straight away”. I was skeptical, unsure, and a little taken aback by the build to start with, but sure enough, every word of that rang true by the end of the day. Especially when he continued down the road home to charge off solar panels while I pulled into the servo!