Advertisement

Advertisement

As we go about modifying our Independent Front Suspension (IFS) four-wheel drives, we often upset the geometry of the suspension and driveline, especially when we lift them. With older solid axle suspension, the axles and CVs remained in line with the diff centre when you installed a lift kit, so aside from castor angles, there wasn’t a great deal you could do to upset your suspension geometry when lifting your 4X4.

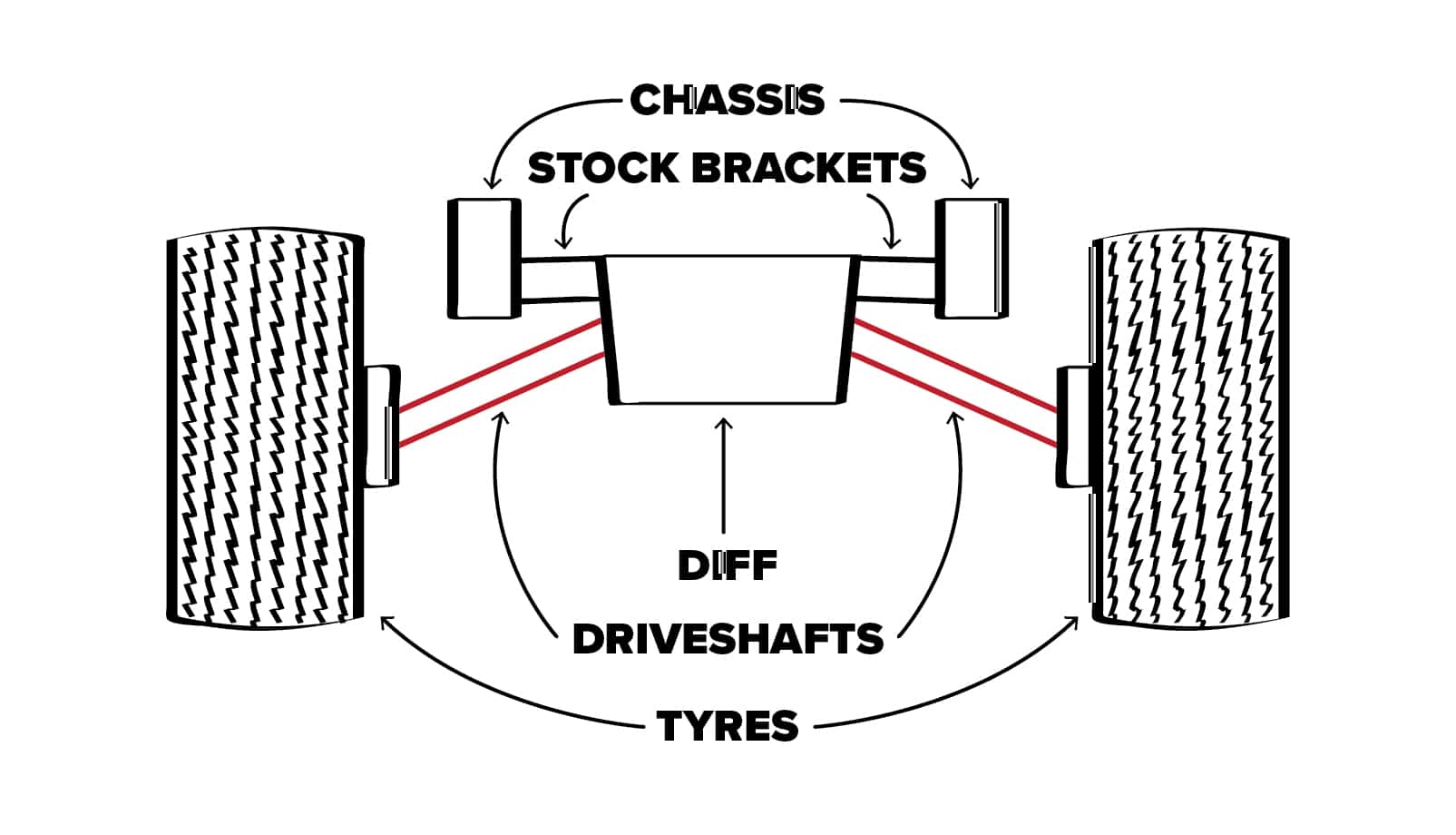

Installing a lift kit into IFS-equipped 4X4s can be problematic because the front diff remains attached to the chassis, however the hub assembly is lowered relative to the diff, dependent on what size lift you install. This often leads to some excessive changes in the suspension and driveline geometry, and in turn, its reliability. The main issue with a lift is the increase to the angle of the CVs from your diff to your wheel hubs.

This will lead to premature failure (the joint itself will wear quicker, the rubber boots start rubbing will wear and then rip, or the CV shaft could be pulled out of the inner joint, or out of the inner stub axle itself) which, if it happens when you’re out on a track will mean ages restoring the thing to a drivable state (a story for another time) or a call to a recovery service and a long wait for a tow truck. Aside from earlier failure through the joint wearing, an increased lift weakens the strength of the CV joint due to the excessive angles at play.

Not exactly. We reckon a lift of around two-inches and bigger would need to look at installing a diff drop kit. And that’s because as the lift increases, so too does the angles that the CVs are on. Basically, as soon as you start lifting your four-wheel drive, the geometry that the original engineers intended goes out the window.

The minimal angle that the CV was on is now increasing, and so its strength is decreased. Putting the same amount of power or strain through a part that due to the geometry changes is weakened, and you’re going to have a bad time. That’s not to say you can’t fit a diff drop if you’re lifting your 4X4 less than two inches because any sort of lift is playing going to change up the geometry, however under two-inches of lift is often within the original tolerances or close enough too. Essentially, the diff drop kit helps you to bring everything back into alignment, improving the geometry of your suspension, and the reliability of the CVs.

As the front diff is mounted to the chassis and diff cross member, once you raise the suspension, the diff is also being raised, which changes your driveline geometry. As we said earlier, where this becomes problematic is that instead of your CV shafts sitting close to level, they will now be angled downward, from the diff to the hub assembly. The angles created when lifting a vehicle can then be exacerbated as we drive; down-travel will increase the angles further – Especially so if you’ve got a wheel in the air (it’s at maximum down travel), and it starts to spin, then lands back on the deck while you’re pinning it – that increased angle due to the lift (without a diff drop), is often enough to blow a CV to pieces.

With the increased angle, the CV joints lose their strength, so are more susceptible to breakage, especially so when at full lock, as this will be straining the CV on two separate axis (both up and down, and side to side). The stub-axle that is inserted into the diff housing is also under increased strain, which increases the chances of the diff carrier bearings and seals failing. Then you’ve got the concern of the CV boots rubbing and wearing through, and also the CV boot is will also be further stretched and under more tension than what it would be without the lift. A diff drop corrects all these issues.

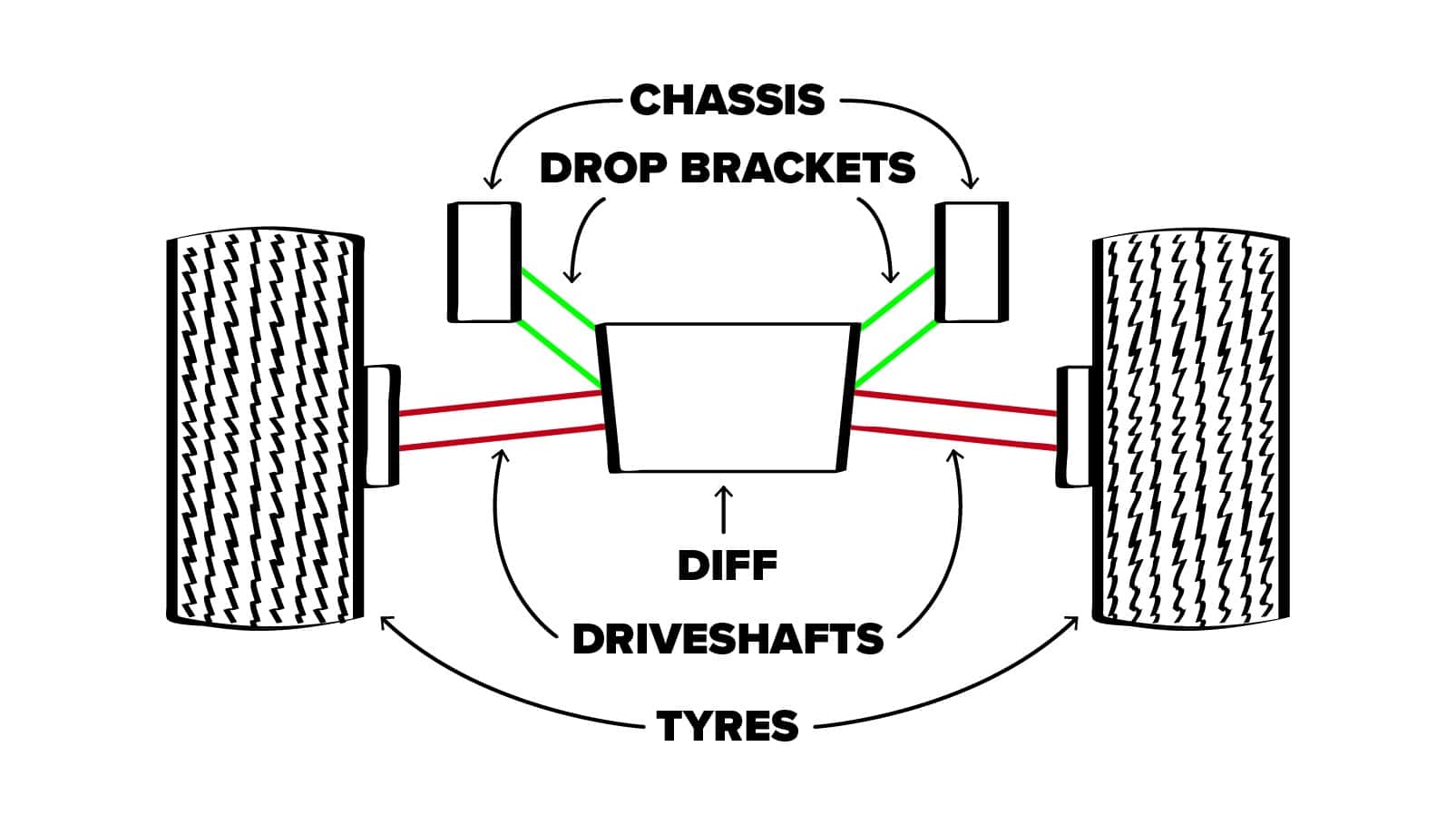

The diff drop kit, as the name implies, lowers your diff, by way of spacers (pucks) or cradles (brackets), to bring the CV angles back into alignment and closer to the factory specifications. This limits the strain on the CVs, hubs, diff bearings and seals. As those who have had the displeasure of breaking a CV halfway through a challenging track can attest, there are few things worse than needing to change out a CV on the side of a track, or halfway across the Simpson Desert.

There are quite a few different options for lowering your diff that will bring the CV angles back to optimum. Some work better than others, and some have changed as technology has improved, so choosing the right kit is crucial. Something that you will need to remember is that when you install a diff drop kit into an IFS vehicle, your diff will be lower. This will make it more susceptible to rock/stump strikes and you will lose some of the clearance (you’ll still have more than the standard vehicle) you have gained under the diff when you first installed the suspension lift kit. Fortunately, a lot of bash-plate manufacturers make under-body armour for use in conjunction with diff drop kits, so you can still protect your diff, engine and transfer case, while still gaining the benefits of having your CVs closer to factory spec.

Spacer or ‘puck’ kits are as simple as they come. They include a set of solid steel spacers for the front diff mounts and another set to space the diff cross member down. Some of the earlier kits only dropped the front mounts, so they aren’t nearly as common as they once were, simply due to the average one-inch diff drop kit, only dropping the CV level by 9.5mm. This is due to the offset angles, and that the CV shafts aren’t in the middle of the area being lowered. So for a loss of one-inch of clearance at the front, you’re only dropping the CVs by 9.5mm.

Newer puck/spacer kits include front and rear spacers that will drop the entire diff by the specified amount, however, are not available for all vehicles, depending on each vehicle design. These are the baseline approach and kits can be purchased for around $150, again, dependant on your vehicle, from various suspension stores or engineering mobs.

The strongest (and most expensive) option, is the billet cradle kit. The billet cradles are, as their namesake suggests, made from a single lump of steel billet and machined to shape with double-ended mounts. Finding one to suit your model may be problematic however. Due to the cost of manufacturing the kits, and their weight, there are fewer manufacturers who make these. Especially as the modern welded arm kits (see below) offer nearly the same level of strength for a fraction of the price and weight.

These kits work as an entirely new set of brackets that your diff attaches to your chassis through. Aside from their increased drop amount over a puck kit, they also replace the stock arms. Those with N70 HiLuxes would have heard of an issue of bending the factory diff mounting brackets through utilising reverse a little aggressively. The torque coming into the front diff is more than the mounts can handle (if you’re a little too aggressive when in reverse in four-wheel drive), and bend the mounts up. This actually increases the height of the diff and makes the CV angles just that much worse.

After the effectiveness of the spacer kits came into question, the welded arm or ‘cradle’ style of diff drop reigned supreme. The early kits completely replaced the diff mounts and cross members to the chassis, allowing the diff and CVs to be dropped by a full 30mm (dependant on the kit). One of their drawbacks was that the early options were usually made from relatively thin folded and welded steel, so there were fatigue and strength issues. Also of concern, is that some of the folds couldn’t be made due to the angles required so often had multiple welds without full penetration. They did, however, offer up the full one-inch or 30mm drop of the CVs.

With further development, there have been good inroads into utilising better materials and welding techniques on the folded steel style diff drop kit. As with most things, you’ll want to steer clear of bottom-basement kits you’ll find online. They’re often made with substandard materials and poor workmanship in the welding. They can be found from many fabrication and off-road engineering shops from around $250 up to $800, dependant on the brand, design, materials and construction.

This will depend on how large your lift is, and which direction you want to go. If you are going to 50mm or beyond with your lift, a diff drop kit would be in yours and your CV joints best interest. Which specific way to go about it will come down to your specific build and suspension height, so contact the folks who installed the lift kit in your 4X4 and have a yarn with them about which kit they have seen work best with the same lift you have.