More goes into your off-road rubber than you’d think – here are 5 things that you may not know about tyres.

1 MODERN TYRE DESIGN CAME FROM A 1920s AMERICAN BUTCHER

Ever felt that your own genius was so far ahead of time it’d take decades before people realised how clever you really are? No? Me neither. But one bloke who can (or could) loudly make such a claim was an American chap by the name of John Sipe in the 1920s. If you haven’t heard of him before, don’t worry – his claim to fame was inventing a system that’d help stop him falling over on the slippery concrete floors in the slaughterhouse where he worked. Apparently, that was an on-going problem for him.

Despite all the jokes, what this clever bugger did would revolutionise tyre design. Well, with a few tweaks it would, anyway. He invented tyre siping (Sipe, get it?). He worked out that by making strategic, thin cuts into the rubber tread on his boots it’d allow the water to be pushed out from under the sole and let the rubber bite into the concrete underneath. Unfortunately when he patented the design for use on solid rubber car tyres, it didn’t work out too well – the rubber was too stiff to take advantage of the relief cuts. His son Harry finally got the ball rolling in a big way when the motoring industry started changing to the inflatable tyres we have today.

2 A TYRE IS LIKE A LAYERED ONION

What has a flexible liner, chunky tread and a steel belt? No; not the local BDSM club. Tyres! Contrary to uninformed belief there’s actually a whole lot of design and construction that goes into each tyre. Your standard everyday tyre is constructed out of a whole heap of materials such as carbon black, silica, nylon, steel, canvas, silk, cotton, kevlar and more types of rubber than what’s found in a teenage boy’s wallet.

In an average tyre, you’ll generally have a thick steel cable giving strength to the bead area. This steel cable will be coated in a rubber extrusion to stiffen the sidewall and give a solid foundation to build the tyre from. From here, there are multiple different layers of rubber compounds making up the carcass and inner liner before various steel belts are laid in place (often in crossing patterns) with fibre top caps. In fact, the rubber we can see is pretty much one of the least significant components of tyre construction.

3 SIDEWALL STAMPINGS ARE ACTUALLY USEFUL

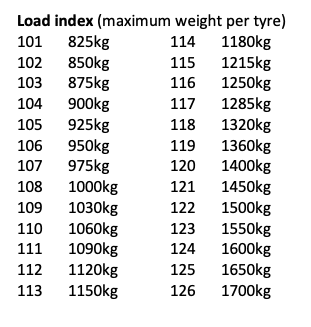

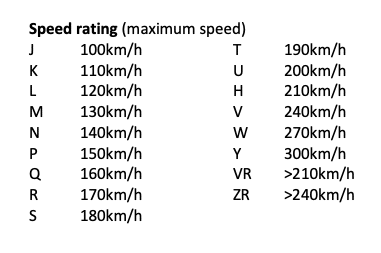

On your average mud tyre, you’d spot something along the lines of LT265/75R16 108T. The LT stands for Light Truck construction (the alternative is P for Passenger construction; more on that later). 265 means there’s 265mm between the sidewalls on the recommended rim size. 75 is the aspect ratio; the total sidewall height would be 75% of the width. R stands for radial construction and 16 stands for a 16-inch rim. From this we can work out we’ve got an overall height of 31.8 inches and a width of around 10.5 inches. The next two numbers are what’s known as the load index, outlined in the handy ‘Load index’ table (below). Finally, the T, which is our tyre’s speed rating. A speed rating of T would mean this tyre is safe up to 190km/h, although that’s not recommended in a 4X4 (see attached ‘Speed Rating’ table).

People have written textbooks on this information, so consider this the abridged version. M+S stands for Mud + Snow. The Temperature, Traction and Treadwear markings all indicate how much heat the tyre can handle, how well it grips in the wet, and how long the tread will last. The rule here is the more As or the bigger the number, the better it is.

4 LIGHT TRUCK VS PASSENGER CONSTRUCTION

For our next point in 5 things you didn’t know about tyres; construction. I touched briefly on LT and P designations earlier. The difference in constructions is huge, and the outcomes even larger. At first a Passenger rated tyre sounds fantastic. They’re designed to maximise handling, ride quality and fuel economy while minimising road noise. Sounds awesome, except it basically does it by being the girlie-man version of a Light Truck (LT) tyre, complete with un-calloused hands and a freshly shaved face. They’re essentially made as light as can be. Thinner sidewalls, thinner tread, thinner belts and a smaller bead design. What this means for us in 4X4 land is they’re more likely to get staked, can’t handle the load of even an unladen 4X4, and are far more likely to spin a bead – leaving you sitting on the side of the track desperately trying to grow a beard to make up for your poor tyre choice.

So why do people keep fitting them to 4X4s? Well, they’re cheaper. They also come in lower profiles for those bling-bling wheels. That’s about it, really. Look at it this way: if it’d make your air conditioning work a little bit better, would you fit smaller brakes to your 4X4? Didn’t think so. Stick with LT tyres on your off-road rig.

5 THEY CAN MELT

You’ve probably heard us squawking before about not running low pressures on the blacktop, and it’s not just because we’re big fans of maximising performance and pretending we’re Steve McQueen through mountain passes (we really are). It does damage, as in potentially life-ending damage.

A tyre is constructed of lots of different layers and parts. When the tyre deforms (the flat bit on the bottom) the bonds that stick those layers together get stretched and pushed, causing heat to build up. At slow speeds off-road it’s not really an issue. But with tyre pressures dropped low and highway speeds, the tyre is excessively stretching and deforming; all while building up heat. This heat can cause the bonds to separate and the tyre to literally fall apart from the inside out. Think of it like death by a thousand cuts. A quick trip down to the servo to fill up probably won’t be an issue; but if you’re doing 50 kilometres up the freeway without airing up, you’d better start wearing a helmet when you drive.

And there you have it; 5 things you probably never knew about tyres. Is there anything else you would add to our top 5 things most folks don’t know about tyres? Let us know in the comments below!